Add-On Instructions

Add-On Instructions

Add-On Instructions are user-defined instructions. When you define an Add-On Instruction in a project it behaves similarly to a built-in instruction. You can define these instructions or they can be provided to you by someone else. An Add-On Instruction enables you to encapsulate your most commonly used logic as sets of instructions. These instructions let you easily reuse sets of commonly used instructions in your projects and share the instructions to promote consistency in all projects.

Create Logic Instruction

Create AOI logic using the standard Ladder, Function Block Diagram, and Structured Text language already available in the Logix Designer application. When created, an Add-On Instruction can then be used in any of the Logix Designer application routines.

Context views, which enable you to visualize the logic for your instruction for a specific instance of its use, simplify online troubleshooting of your Add-On Instructions. Auto-generated topic help also makes it easier for you to get the help you need for a successful implementation.

Finally, use the Add-On Instructions’ source protection capability to limit a user of your instruction to read-only access or to allow no access to the internal logic or local tags used by the instruction. This prevents unwanted changes to your instruction as well as protects your intellectual property.

In summary, Add-On Instructions enable you to:

- Define instructions that you can write and reuse across multiple projects.

- Export an Add-On Instruction to an .L5X file that can then be imported into another project. You can also copy and paste between projects.

- View revision history, change history, and an auto-generated help page for each instruction.

- Protect their use and modification by applying permission set to each instruction or by using source protection.

- Prevent modification, track revisions, and easily confirm instruction functionality for Add-On Instructions by adding an instruction signature to your Add-On Instruction, which generates a unique identifier and prevents (seals) the instruction from being edited. When a sealed instruction is exported to an .L5K or .L5X file, the instruction is encoded.

Add-On Instruction Signature

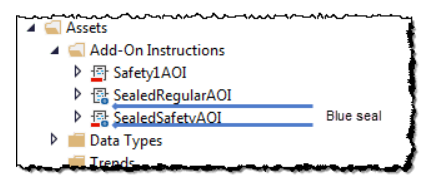

The Add-On Instruction signature is checked at each download to verify that the Add-On Instruction parameters, local tags, and logic are unchanged. The instruction signature is also checked when the controller is verified (the Safety Signature ID is checked only at download). When the instruction signature has been generated, the Logix Designer application displays the instruction with a blue seal icon, as shown below.

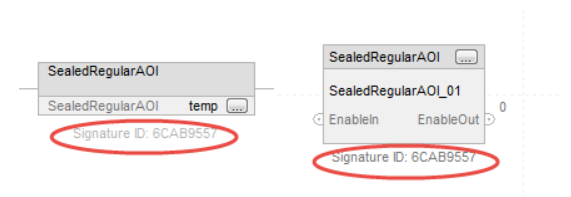

When an instruction is sealed, the instruction signature is displayed on the faceplate of the instruction in the Ladder Diagram Editor and the Function Block Diagram Editor, as shown here:

You can turn on or off the display of the signature ID in the Workstation Options dialog box of the Logix Designer application. To access the Workstation Options dialog, choose Options from the Tools menu. See Viewing and Printing the Instruction Signature for more information.

You can also view the instruction signature and the safety instruction signature on the Quick View pane of the Controller Organizer and on the Signature tab of the Instruction Definition Editor dialog box.

Permission sets for Add-On Instructions

Logix Designer projects are secured using FactoryTalk Security. To secure parts of a project with different permissions, apply permission sets to individual tags, routines, and Add-On Instructions. For example, you can apply permissions that allow a user to modify some tags, but not others. The security settings that you apply to a specific component override any security policy applied to the overall project.

Keep the following considerations in mind when applying permission sets to components:

- Permission sets can be applied only when the overall project has been secured.

- A permission set that restricts viewing an Add-On Instruction or routine in the Logix Designer. The application does not prevent a user from exporting and viewing the Add-On Instruction or routine in cleartext. To prevent exporting the component, configure the permission set to deny the Project: Export permission.

- To apply permission set to a component, users must have Component: Modify Permission Set privileges, which are configured in FactoryTalk Security.

- The permission set that you apply to a component overrides the permissions applied to the entire project.