Assign an IP Address within the Studio 5000 Environment

If a Logix Designer project is online with a controller that communicates to or through the EtherNet/IP communication device, you can use the Logix Designer application to assign an IP address.

To use the Logix Designer application to set the communication device’s IP address, follow these steps

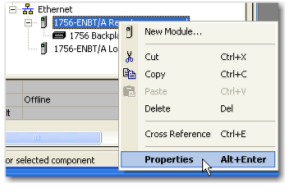

1. In the Controller Organizer, right-click the EtherNet/IP device and choose PropertiesIn the Controller Organizer, right-click the EtherNet/IP device and choose Properties.

2. Click the Port Configuration tab.

3. In the IP Address field, type the IP address.

4. In the other fields, type the other network parameters, if needed.

5. Click Apply.

6. Click OK.

Reset to Factory Default You can reset the device’s IP address to its factory default value with the following methods:

• If the device has rotary switches, set the switches to 888 and cycle power.

• If the device does not have rotary switches, use a MSG instruction to the reset the IP address.

IMPORTANT: The fields that appear vary from one EtherNet/IP device to another.